Description

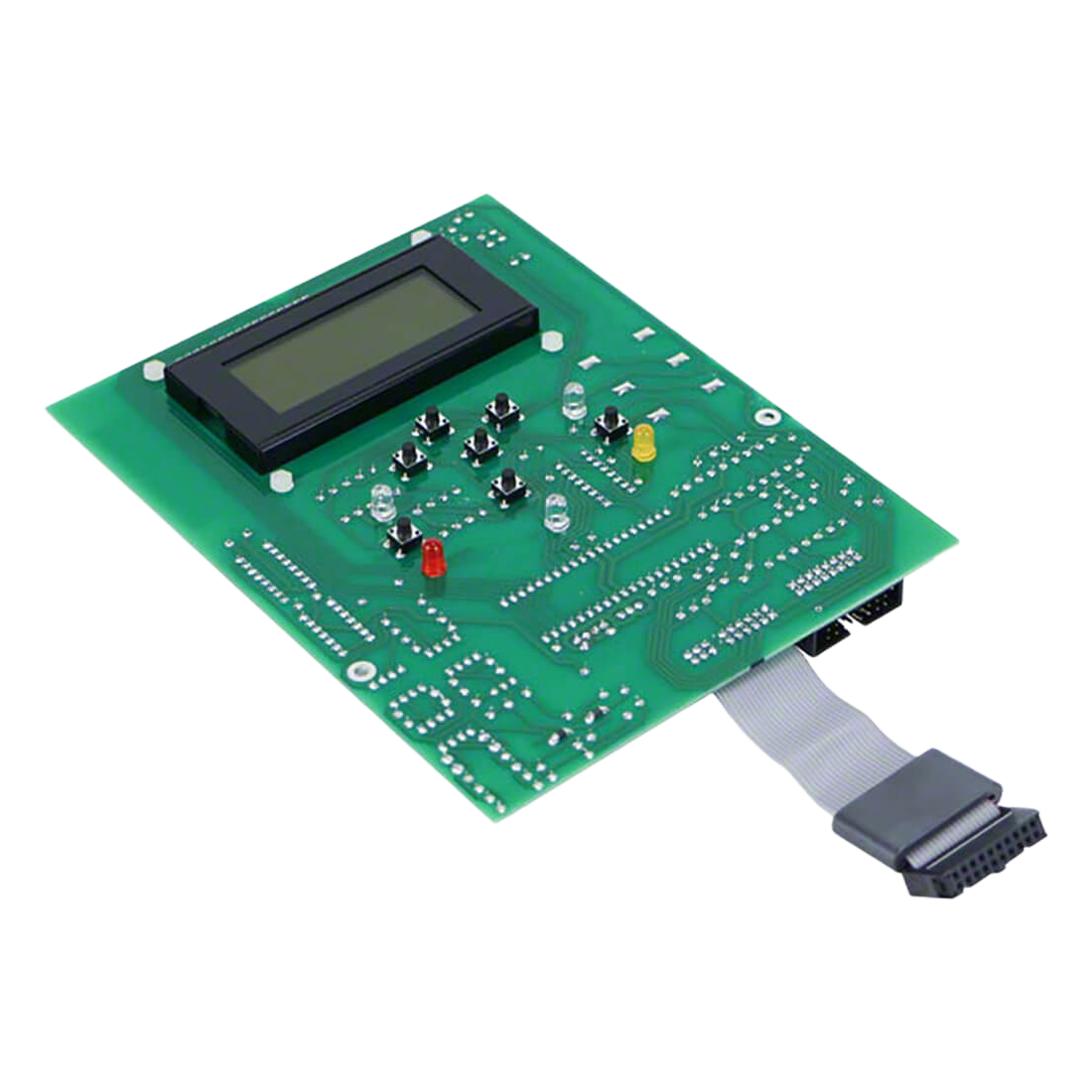

Zodiac Hydroxinator control electronic board R0615400

The Zodiac Hydroxinator control electronic board R0615400 is the genuine main control PCB for Hydroxinator MagnaPool systems and selected Tri and Tri Expert

salt chlorinators. It manages cell power, monitoring and user interface functions, so replacing a faulty board restores stable operation and reliable

chlorine production.

Role of the control electronic board

This control board is the central part of the Hydroxinator and compatible Tri units. It processes information from sensors, applies safety checks and

regulates the power sent to the salt cell according to the selected output level. It also manages alarms and communicates with the front control panel,

so a healthy PCB is essential for everyday use of the chlorinator.

Compatibility and references

The R0615400 board is used as the control electronics in Hydroxinator MagnaPool systems and as a replacement for earlier Tri control boards that have

been discontinued. It appears in exploded views as “Hydroxinator control PCB” or “control electronic board” with the same reference.

- Genuine control PCB for Hydroxinator and Hydroxinator iQ MagnaPool units.

- Replacement for earlier Tri control boards on Tri and Tri Expert models where W082993 is superseded.

- Suitable for Tri 10, 18, 22 and 35, Tri Expert 10, 18, 22 and 35 and Tri Expert LS 10 and 18 when specified.

- EAN code commonly associated with this board: 9317545021294.

Before ordering, always check the identification label on your chlorinator and the official spare parts diagram. If the parts list specifies

“control electronic board” with reference R0615400 for your model, this PCB is the correct replacement.

Typical symptoms of a faulty control board

Because the control board works in a warm, humid environment and drives the cell at relatively high current, components can age or fail over time.

When this happens, the chlorinator may no longer operate correctly even though the cell and cabling are in good condition.

- The unit does not power up despite a correct mains supply and intact fuse.

- Repeated electronic or cell errors that persist after replacing the cell and checking wiring.

- Random shutdowns or resets during operation without external cause.

- Visible marks, discolouration or deformation on components of the existing board.

Installation and replacement guidelines

Replacing the Zodiac Hydroxinator control electronic board R0615400 involves working inside the control box. The work should be done with the unit

fully isolated from the mains and ideally by a qualified technician familiar with pool electrical equipment.

- Disconnect the chlorinator from the mains and confirm that there is no voltage present.

- Open the control unit housing and take clear photos of the existing board and all its connectors.

- Unplug the cell leads, sensor cables and front panel connections from the old PCB.

- Remove the fixing screws, take out the old board and keep any spacers or supports.

- Position the new R0615400 board in the same place, refit the screws and ensure it sits flat on its support.

- Reconnect all cables one by one, following your photos and the wiring diagram in the manual.

- Check that no wires are trapped and that ventilation openings and any cooling fan are unobstructed.

After reassembly, close the housing, reconnect the mains and run a test cycle to confirm that the unit powers up correctly, the cell is detected and

the output can be adjusted without new error messages.

Good practice to protect the new PCB

Once the new Zodiac Hydroxinator control electronic board R0615400 is installed, a few simple measures help to extend its service life.

- Keep the technical room dry, well ventilated and away from direct chemical vapours.

- Maintain correct salt level, cell sizing and output settings to avoid unnecessary electrical stress.

- Ensure that the cooling path around the board and any fan is free from dust and obstructions.

- Inspect wiring connections periodically for signs of overheating or loosening.

With proper installation and basic preventive care, this genuine Zodiac PCB allows Hydroxinator and compatible Tri systems to run reliably for many

seasons, maintaining precise control of salt chlorination in the pool.